Tungsten Nickel Iron Alloy

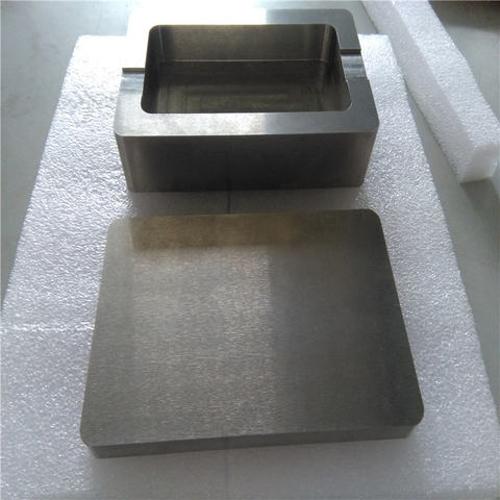

Tungsten-nickel-iron alloy is a kind of alloy composed of tungsten as the base, adding a small amount of nickel, iron and other alloying elements, with high density, high strength, good ray shielding ability. Excellent processability and weldability. The density of this alloy is usually between 16.5-18.75g/cm3, the tensile strength is 700-1000Mpa, with a large thermal conductivity (5 times that of mold steel), a small coefficient of linear expansion (5 times that of mold steel), and a small coefficient of thermal conductivity (5 times that of mold steel). Smaller linear expansion coefficient (only 1/2-1/3 of iron or steel), and better electrical conductivity and plasticity. These properties of tungsten-nickel-iron alloys have led to a wide range of applications in many fields, including but not limited to radiation protection and guidance, industrial counterweight components, security and defense parts, etc..

Radiation protection and guidance: Due to its high density and excellent X-ray and gamma-ray absorption, tungsten-nickel-iron alloy is an ideal material for radiation therapy collimators and protection components, and is widely used in various types of medical imaging equipment and radiotherapy, Nuclear medicine and other fields.

Industrial counterweight parts: In aerospace, automotive industry, sports equipment, crude oil and natural gas drilling, tungsten-nickel-iron alloy is used as a counterweight part to compensate for tungsten-nickel alloys are used as counterweights in the aerospace and automotive industries, sports equipment, crude oil and gas drilling, etc., to ensure excellent balance by compensating for oscillations, weight shifts, imbalances and vibrations.

Components for security and defense: In modern warfare and the defense industry, tungsten-based high specific gravity materials are indispensable due to their high density, high storage speed, and high penetration capacity.

In addition, tungsten-nickel-iron alloys are environmentally friendly and non-toxic compared to lead, and have a certain degree of ferromagnetism compared to tungsten-nickel-copper alloys, which has better mechanical properties and processing performance.