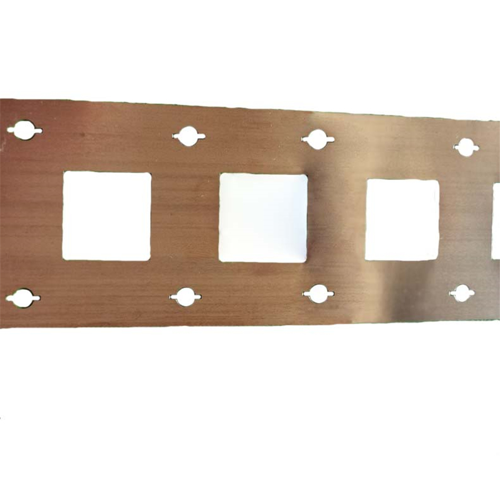

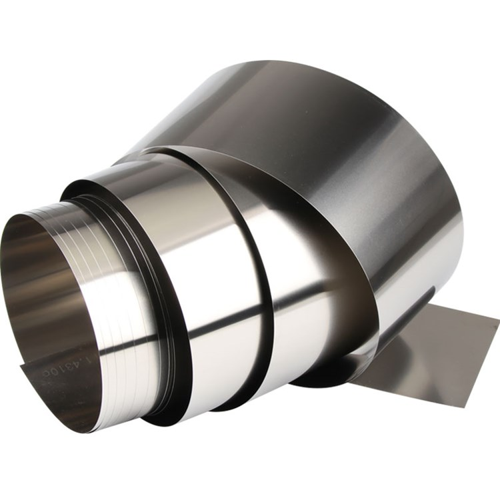

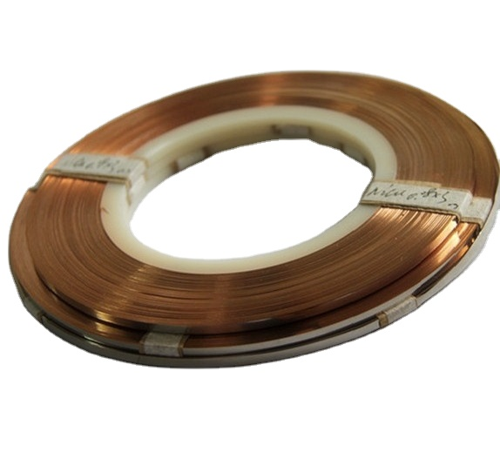

Nickel plated strip

Nickel-plated strips are used primarily for protective decoration, improved wear resistance, and specific industrial applications.

Nickel-plated strips are primarily used as protective decorative coatings and are cathodic for iron substrates. Due to its high porosity, copper plating is often used as a base layer or multiple layers of nickel plating are used to improve corrosion resistance. This plating is very stable in air and resistant to atmospheric, alkali and some acid corrosion, thanks to the strong passivation ability of nickel, which can quickly generate a very thin passivation film on the surface, which is very thin, and which can be used to protect the nickel substrate from air. Insulate the nickel substrate from contact with air. In addition, through the use of certain brightening agents, it is possible to obtain a mirror-bright nickel coating directly in the plating solution, which further enhances its decorative properties.

The high hardness of the nickel plating layer can improve the wear resistance of the surface of the product. In the printing industry, nickel plating is often used to increase the hardness of lead surfaces, demonstrating its importance in specific industrial applications.

In addition, black nickel plating is mainly used in optical instruments for parts that require matting, indicating that nickel-plated strips are not limited to traditional protective decorative and wear-resistant applications, but also extend to more specialized technical areas.

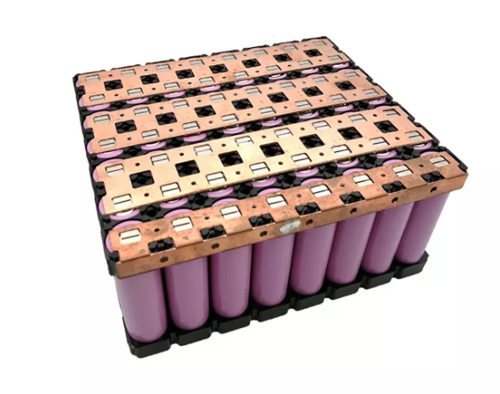

In summary, nickel-plated strips are widely used in industrial products such as automobiles, bicycles, clocks and watches, medical devices, etc., due to their excellent corrosion resistance and hardness, as well as in Printing industry, etc., and is generally used mostly as an intermediate layer.