Tungsten Alloy

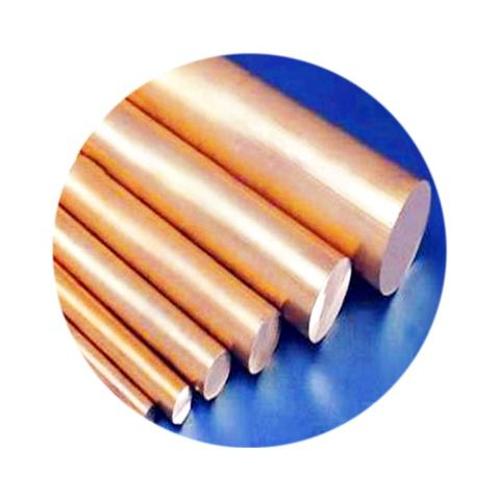

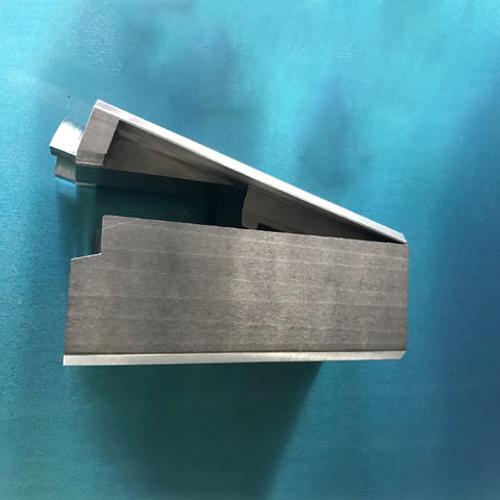

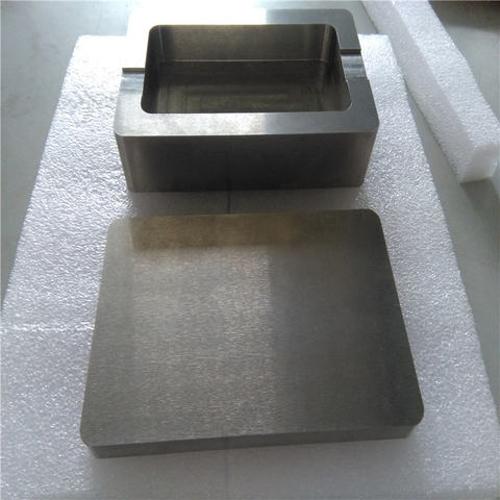

Tungsten alloy is a kind of alloy material composed of tungsten and other metal elements (such as Ni, Co, Mo, etc.), with high density, high strength, High density, high strength and high hardness, so it is also known as "3 high" or "3H" alloy. This alloy material in the preparation process, through the addition of appropriate amounts of other metal elements, can significantly improve its physical properties, such as hardness, ultimate tensile strength, yield strength, elongation, etc.. strength, elongation, etc. The density of tungsten alloys ranges from 15.00g/cm³ to 18.50g/cm³, and the tungsten content is usually distributed between 79%W and 97%W. According to different product applications and working environment requirements, tungsten alloys can be categorized into several series, such as W-Ni-Fe, W-Ni-Cu, etc., to meet specific performance requirements.

Tungsten alloys have a variety of excellent properties, including high hardness, wear resistance, better strength and toughness, heat resistance and corrosion resistance. These properties make tungsten alloys widely used in several industries, such as the defense industry, aerospace industry, medical industry, and electrical industry. For example, tungsten alloy blocks are commonly used in the manufacture of counterweights and some parts used in high-strength environments, while tungsten alloy counterweights are widely used in crankshafts, aerospace use, marine use, sports equipment and other fields. In addition, tungsten alloy is also used in the manufacture of medical shielding parts and other parts due to its good electrical properties, thermal conductivity and low coefficient of linear expansion, as well as good corrosion and oxidation resistance.