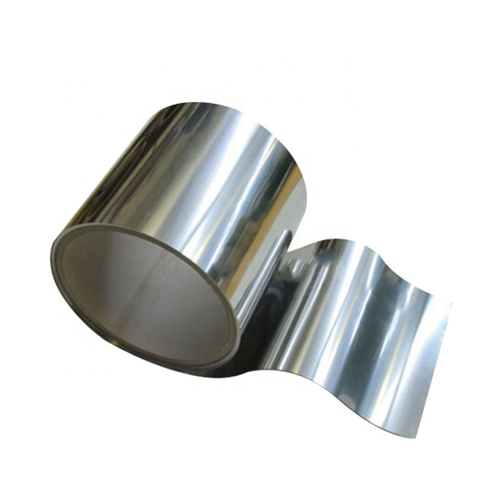

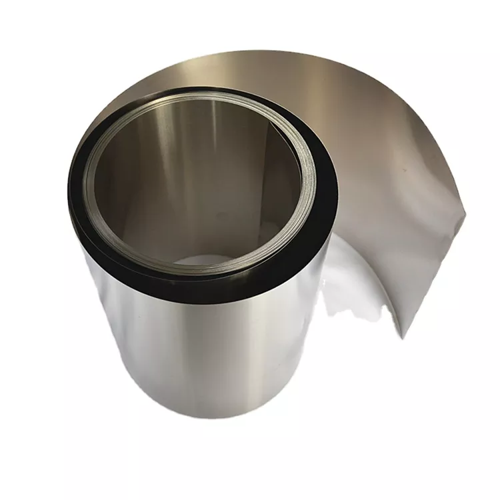

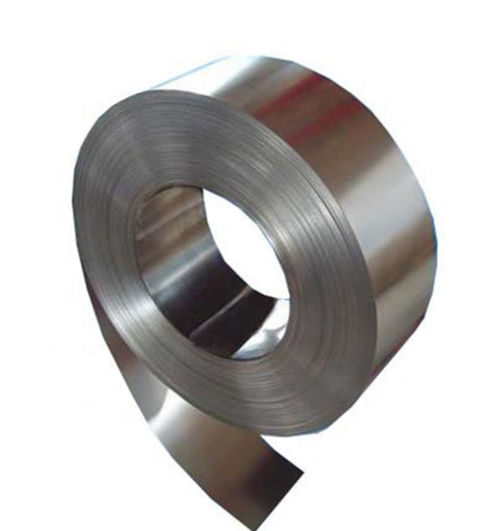

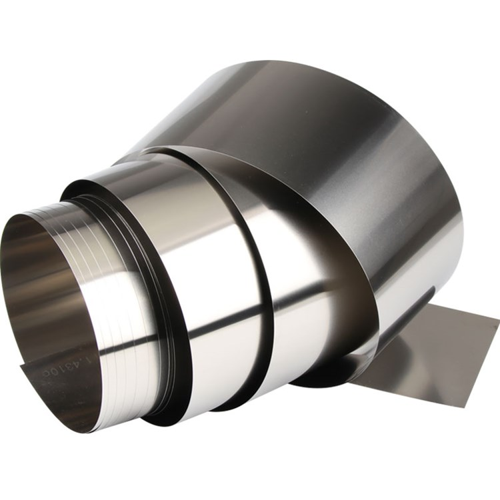

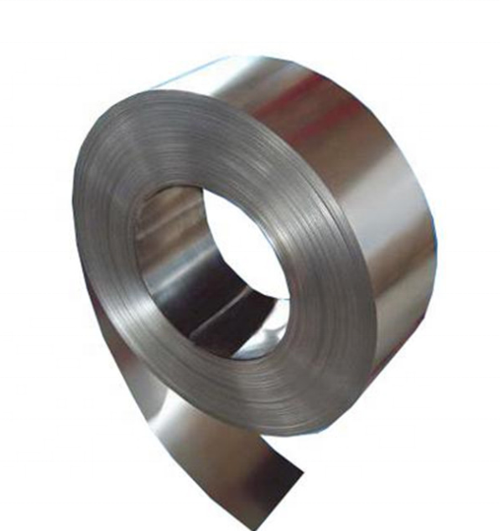

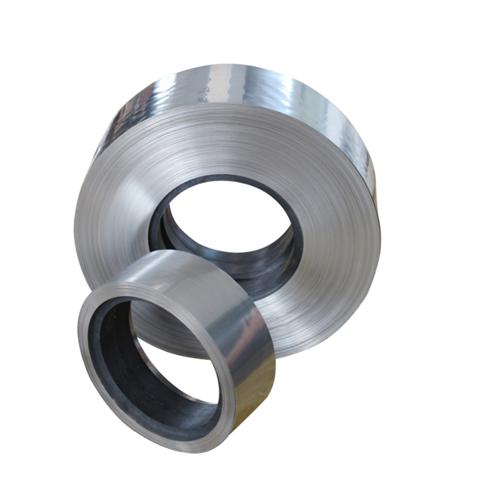

zinc foil

Zinc foil is a thin sheet material processed using metallic zinc, which has good electrical conductivity and corrosion resistance. It is commonly used in electronic products, batteries, construction materials, anti-corrosion coatings and other fields. The production process of zinc foil mainly includes raw material selection, hot rolling, surface treatment, cutting and other steps. First, zinc metal is obtained by melting zinc ore, then it is heated to the melting point and hot rolled to the required sheet thickness. Next, surface treatment of zinc foil is needed to improve its corrosion resistance and mechanical properties. Finally, it is cut to the required size according to customer requirements.

Zinc foil has many advantages, including excellent electrical conductivity, which makes it suitable for use in electronics and batteries. In addition, zinc foil has good corrosion and oxidation resistance, which improves product life and stability. Zinc foil also has excellent plasticity and processability, allowing for stamping, bending and other processing. As an environmentally friendly material, zinc foil can be recycled without polluting the environment.

In the field of electronics, zinc foil is often used to make electrodes for batteries to provide good electrical conductivity and oxidation resistance. In the field of building materials, zinc foil is often used as a roofing material to prevent rainwater infiltration and to prevent rusting of zinc products. In the field of anti-corrosive coatings, zinc foil is often used as a coating material to improve the corrosion resistance of products.