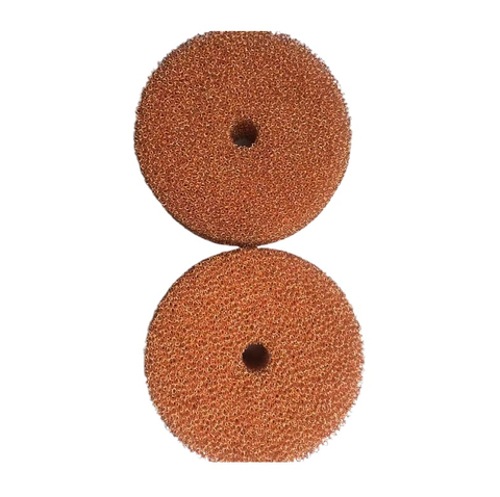

Foam Alloy

Foam alloys are alloys with a unique pore structure that combine lightweight, robustness, excellent thermal conductivity, and large specific surface area, resulting in a wide range of applications in a variety of fields.

Material Properties.

Light and strong: The light and strong structure of foam alloys is due to their porosity, which reduces the density of the material. For example, copper foam can easily reach a density of 0.4-1.8 g/cm3, which is several times lower than that of ordinary copper materials, but still has good strength and stiffness.

Excellent thermal conductivity: Foam alloys are widely favored for their good thermal conductivity. The thermal conductivity of copper foam can reach 100-400W/(m-K), which is several times or even hundreds of times higher than that of ordinary solid materials. This allows foam alloys to perform excellent thermal conductivity in high temperatures or in environments where heat dissipation is required.

Large Specific Surface Area: The pore structure of foam alloys gives them a large specific surface area, which gives them potential for a wide range of applications in areas such as catalysis, filtration and adsorption. For example, copper foam can be used as a catalyst carrier to improve reaction efficiency and catalyst utilization by increasing its surface area.