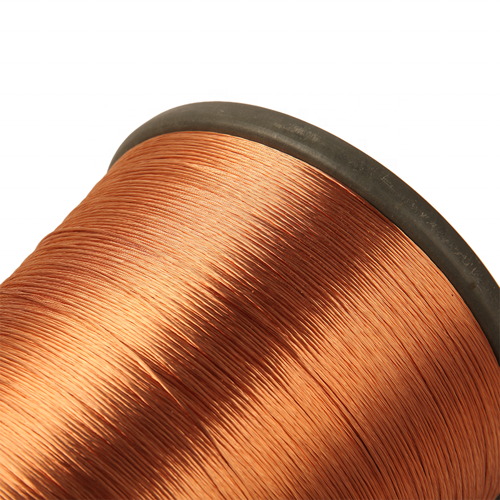

Copper Alloy

Copper alloys are alloys made of pure copper with the addition of one or several other elements.

There is a wide variety of copper alloys including, but not limited to, bronze, brass and white copper. Bronze refers primarily to copper-tin alloys, while copper alloys other than brass and white copper are often referred to as bronze. Tin bronze is commonly used in the manufacture of bearings, worm wheels, gears, etc. due to its good casting properties, friction-reducing properties and mechanical properties. Lead bronze is widely used as bearing material for modern engines and grinding machines. Aluminum bronze because of its high strength, good wear resistance and corrosion resistance, suitable for casting high load gears, bushings, marine propellers and so on. Phosphor bronze and beryllium bronze are suitable for the manufacture of precision springs and electrical contact components, as well as non-sparking tools due to their high elastic limit and excellent electrical conductivity, respectively. Beryllium copper, as a supersaturated solid solution copper-based alloy with good mechanical, physical, chemical and corrosion-resistant properties, is commonly used in powder metallurgy to make and high-temperature superhard alloy molds1.

Classification methods of copper alloys include division by alloying system (e.g., unalloyed copper and alloyed copper), division by function (e.g., copper alloys for electrical and thermal conductivity, copper alloys for structural use. corrosion-resistant copper alloys, etc.) and by material formation method (e.g., casting copper alloys and deformed copper alloys). These classifications help to select the right copper alloy material for the specific application.