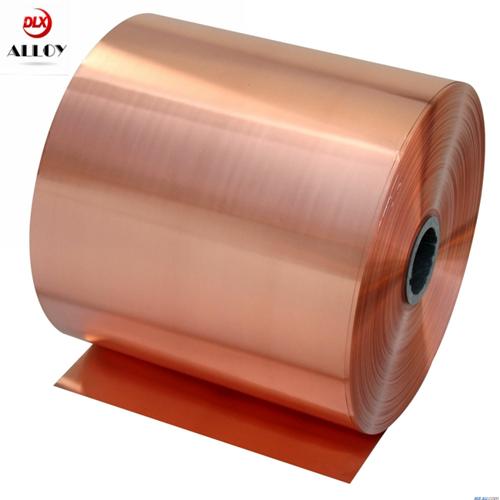

Copper Foil Strip

Copper foil is an anionic electrolytic material, which is a continuous metal at the bottom of a circuit board. Copper foil is characterized by being very thin and can be used as a PCB conductor.

Generally speaking, it is glued on top of the insulating layer, and the corresponding protective layer is formed on the surface through the printing process, and then a circuit pattern is formed through corrosion. Copper foil can be divided into two categories, calendered copper foil and electrolytic copper foil, according to its manufacturing process. Calendered copper foil is a product made by repeated rolling and annealing of high-precision copper strips using the principle of plastic processing, with a thickness of 4-100 microns and a width of less than 800 millimeters.

Calendered copper foil is superior to electrolytic copper foil in terms of ductility, bending resistance and electrical conductivity, and its copper purity is also higher than that of electrolytic copper foil. Electrolytic copper foils, on the other hand, are made by electrolyzing copper using electrochemical principles, and their production costs are relatively low. Calendered copper foil is widely used in flexible copper-clad laminate (FCCL), flexible PCB (FPC), 5G/6G communication, electromagnetic shielding, heat dissipation substrate, graphene film preparation, batteries, and other applications. Graphene film preparation, batteries, LEDs, smart cars, drones, wearable electronics and other industries.